AAC plant system design

Dongyue Machinery Group is one of the most professional manufacture for AAC production line and block making machine . With more than 400 of the AAC production lines all over the world , Dongyue Machinery Group have cooperation with YTONG for the new production technology, production of aerated concrete in all aspects of raw ingredients, production control and other precision cutting its own automatic control system, the pursuit of maximizing equipment life, and always to do everything for outputs best AAC 'product philosophy thus making high-quality aerated concrete products are effectively guaranteed.

After one year study and infer, AAC-CONCEPT Gmbh Germany Dongyue make a technical cooperation agreement in year 2013. the cooperation will include the full set of YTONG Authorize all its drawings, process layout technology to transmit, process recipe debugging, new product development to Dongyue.

Working process

Material dealing process

Put the fly ash or sand into the ball mill to mill via the conveyor belt, after milling, put the slurry into the slurry storage tank by slurry pump.

The lime, cement will convey by conveyor to the dry powder measure scale to scale separately. The slurry convey by slurry pump then to the automatic scale;the power and slurry put into the mixer,pouring into the mould.

After slurry pouring into the mould, put the mould box into the curing room with 50~70℃. After 2-3 hours curing,the blocks become solid

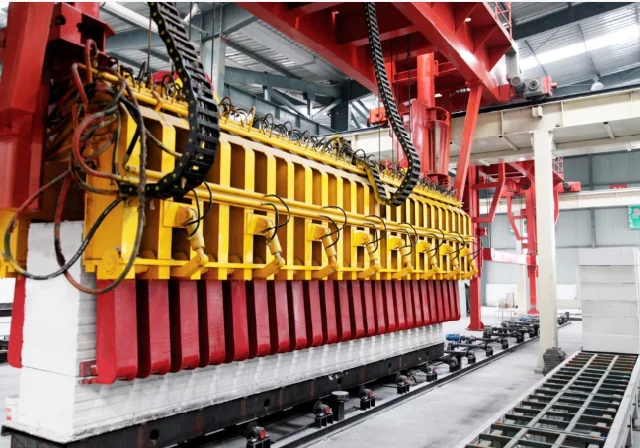

Using reversal crane carry the mould and block to demould on cutting cart. The cutting cart will take the block to level cutting machine,vertical cutting ,two sides cutting,and remove the top waste material.

Finished cutting using semi-product crane carry to the front of autoclave grouped,hoisting machine or dragger will drag steam trolley into autoclave to steam,it need 10-12 hours.

Finished product out of autoclave,with separting machine to separate layer by layer.

Using finished block carry hanger clamp the finished product to package line on wooden pallets,after package, then by forklift transport the finished products to piled yard according to specifications to stack.

Light weight fly ash aac building brick/block plant(40 lines abroad in 6 countries,20 lines in India) raw material description

Fly-Ash:A lot has been said about this raw material in this Project Profile itself. But this Raw material is freely available in Thermal Power plants. There are no taxes on this item whatsoever. Transportation charges are only to be attended by the entrepreneur.

Sand (65-70%): the core raw material of AAC product; the main resource of silica-aluminum components; correspond with JC409-91; the clay should less than 4%

Lime(12-20%):one of the main raw materials of fly ash AAC; the main effect is to provide efficient calcium oxide with cooperation of cement making calcium oxide react with SiO2,Al2O3 in hot water then to produce calcium silicate hydrate. Therefore, lime is also the main resource of strength. Effective calcium oxide of lime should not less than 65%, over 80% is perfect and should accord with JC/T621-1996.

Cement(8-10%): This Project aims to utilize OPC cement as main binder material. It will give faster strength to the bricks, besides giving improved consistent quality. It also ensures a better cost effectiveness for the same. Using OPC will be a standardized practice. The other prime advantages of using OPC (compared to other binders) is it's easy availability locally through nationwide Retail Network of Cement Companies.

Gypsum(1-2%):Gypsum is the foaming regulator in AAC which dispels quicklime and postpones slurry's densification.CaSO4 should be more than 70%.

Aluminum Podwer(0.074%):it is the forming agent type and recommendation for supply depend on raw materials and mix formula

AAC plant Customer

AAC block display

AAC is one of the major achievements of the 20th century in the field of wall construction. It is a revolutionary material offering an unique combination of high durability and strength, low weight, unprecedented buildability and superior ecological green features.

• AAC is a high-quality, non-load-bearing and extremely well insulating building material produced as standard or mega blocks or panels.

• AAC is a long proven material. It has successfully been used in world since early last century and is now among the mostly used wall building materials in Europe with rapidly growing market shares in Asia, the Middle East and recently America.

Contact: Elva

Phone: 008617861607753

Tel: 0086-539-8036228

Company: Dongyue machinery group

Add: Dongyue Technology Industry Area,Linyi City, Shandong Province, China